인공지능 추론 칩은 시장 우위를 점하고 PCB 산업 사슬 가격 상승이 계속될 가능성이 높습니다.

2026-03-04

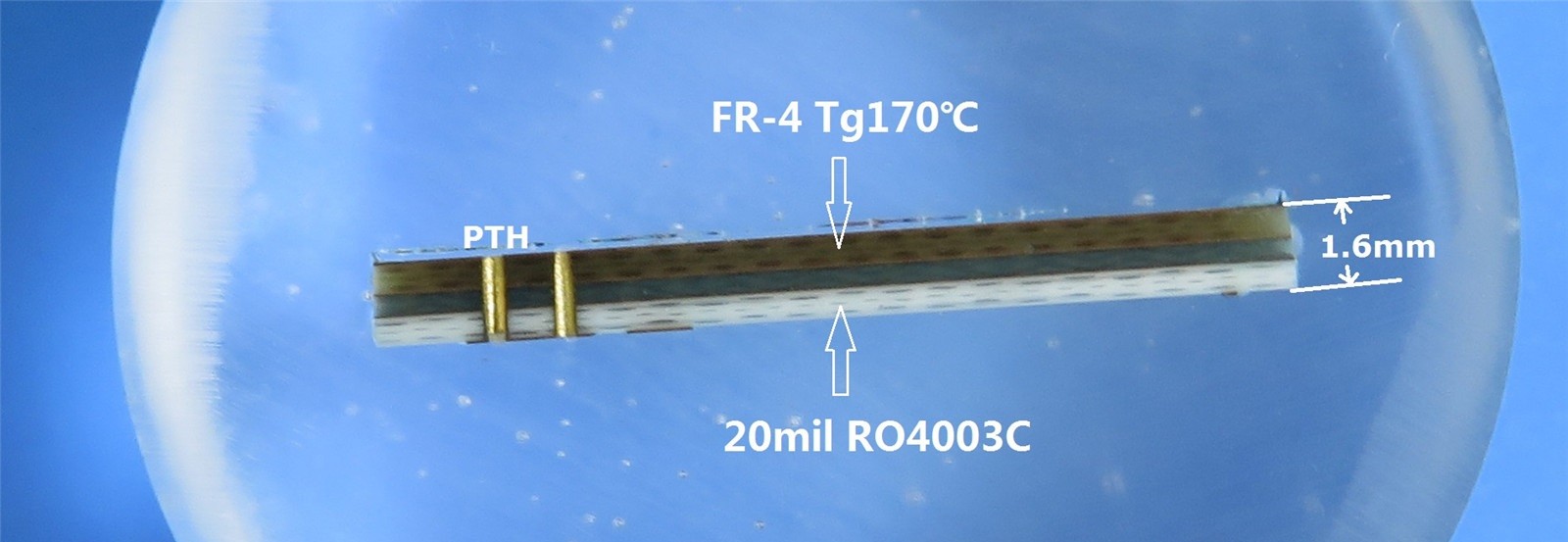

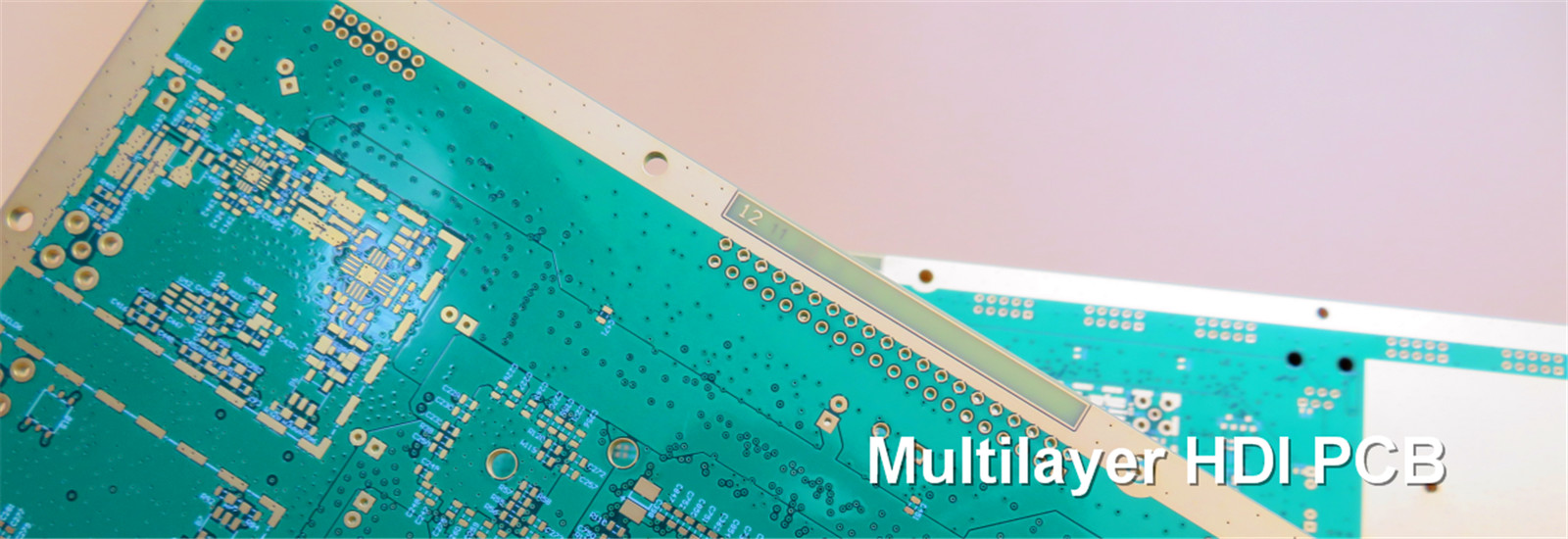

3월 3일 (차이신) – 강력한 AI 수요에 힘입어 PCB(인쇄 회로 기판) 산업 체인의 가격 인상 주기가 계속되고 있습니다. 최신 업계 소식에 따르면 일본 반도체 소재 대기업 레조낙(Resonac)이 3월 1일부터 CCL(동박 적층판) 및 접착 필름 가격을 30% 인상했습니다. 업계 관계자들은 레조낙의 가격 인상이 MLCC(다층 세라믹 커패시터 - 참고: MLCC 자체는 다른 부품이지만, 문맥상 MLCC용 동박 적층판 또는 관련 재료를 지칭하는 것으로 보임), HDI(고밀도 인터커넥트) 기판, IC 기판, 고주파 고속 PCB와 같은 고급 제조 부문으로 확산될 것으로 예상하고 있습니다.

더욱이 PCB 부문은 NVIDIA의 LPU(언어 처리 장치) 추론 칩이라는 슈퍼 촉매를 곧 받게 될 것입니다. 시장 분석가들은 AI 애플리케이션의 구현과 규모의 급격한 성장으로 인해 전용 AI 추론 칩 시장이 빠르게 확대될 것으로 믿고 있습니다. 이는 PCB 산업에 심오한 영향을 미쳐 물량 및 가격 동시 상승, 공정 업그레이드, 재료 혁신, 산업 집중도 증가를 주도할 것입니다. 결과적으로 이는 AI 칩 내에서 PCB의 가치와 중요성을 향상시켜 PCB 산업에 완전히 새로운 시장 규모의 여력을 열어줄 것입니다.

----------------------------------------------------

출처: 상하이 증권 뉴스

면책 조항: 우리는 독창성을 존중하며 공유의 가치도 인정합니다. 텍스트와 이미지의 저작권은 원저작자에게 있습니다. 재인쇄의 목적은 더 많은 정보를 공유하기 위한 것이며, 이 계정의 입장을 나타내는 것은 아닙니다. 귀하의 권리가 침해된 경우 즉시 저희에게 연락하여 삭제해 주시기 바랍니다. 감사합니다.

더 보기

중동 분쟁이 주요 PCB 회사들의 주문에 미치는 영향은 얼마나 중요한가?

2026-03-04

중동 분쟁의 강도는 시장의 기대치를 초과하고 있습니다.이란은 여러 차례 보복을 시작했습니다.호르무즈 해협을 통한 항해에 대한 위험은 증가하고 있으며, 글로벌 공급망 장애를 더욱 악화시키고 있습니다. PCB 산업은 구조적 격차를 경험하고 있습니다.선도 기업들의 장점이 점점 더 두드러지고.

2월 27일 현재 퉁후아션 재무 데이터베이스의 자료에 따르면 국내 대표 PCB 기업들의 시가총액은 모두 1000억 위안을 넘어섰다.우스 인쇄회로 (Kunshan) Co.., Ltd는 160,877 억 위안의 총 시장 가치를 달성하여 PCB 개념 부문에서 4위를 차지하여 이러한 최상위 기업의 시장 인정을 강조합니다.

국내 PCB 산업의 선두주자로서, Wus PCB의 최근 운영 데이터는 인상적이었습니다. 특히 주요 플레이어들 사이에서 주문이 집중되는 분명한 추세입니다.미국-이란 분쟁과 인공지능 컴퓨팅 전력 수요의 급증으로 인해, 고품질 PCB 제품에 대한 회사의 주문권은 가득 차 있습니다. 특히 액체 냉각 서버와 관련된 PCB 조달은 전년 동기 대비 310% 증가하여 핵심 성장 엔진이되었습니다.중국 인사이트 컨설팅의 자료에 따르면2025년 6월 30일 기준, Wus PCB는 데이터 센터 PCB 분야에서 10.3%의 세계 시장 점유율을 차지하고 있으며 22층 이상의 고급 PCB의 세계 시장 점유율은 25.3%에 달합니다.세계 1위, 상당한 기술 및 시장 이점을 입증합니다.

업계 분석가들은 미국과 이란의 갈등이 원유와 유리섬유와 같은 PCB 원자재의 비용을 높이고 있다고 지적합니다.생산 비용의 30%를 차지합니다.구리 래미네이트 가격의 10% 상승은 PCB 비용을 직접적으로 5-7% 증가시켜 중소 제조업체의 이익 마진을 더욱 압축합니다.분쟁은 해외 공급망에 불확실성을 심화시킵니다.생산 능력, 기술, 공급망 회복력 부족으로 인해,중소 및 중소 PCB 제조업체에 대한 주문은 안정적인 공급을 할 수있는 선도 기업으로의 전환을 가속화하고 있습니다.우스 PCB는 고급 통신 보드 및 서버 보드 부문에서 깊이 자리 잡고 있으며, 주요 하류 서버 제조업체와 깊이 통합되어 있습니다.또한 1개의 대량 생산을 달성한 최초의.6T 스위치 PCB, 산업 선도적인 수준의 제품 생산량.액체 냉각 서버 PCB 제품은 친환경 컴퓨팅 전력 개발 추세에 부합하고 고 전력 밀도 컴퓨팅 클러스터의 열 분산 요구를 충족합니다.국내 액체 냉각 시장은 2026년에 1050억 위안으로 증가할 것으로 예상되며, 이는 회사에 성장할 방안을 제시합니다.

또한, 글로벌 AI 컴퓨팅 파워 인프라의 가속화와 군사 전자 장치에 대한 수요 증가는 고급 PCB에 대한 수요의 성장을 더욱 촉진시키고 있습니다.글로벌 데이터 센터 액체 냉각 시장은 2026년에 116 억 위안에 달할 것으로 예상됩니다., 전년 동기 대비 거의 60% 증가하여 고품질 PCB에 대한 조달 수요를 직접 자극합니다.레이아웃, 우스 PCB는 현재 昆山, Huangshi, Jintan, 태국에서 5개의 생산 기지를 운영하고 있습니다. 태국 기지는 73에서 운영되었습니다.2025년 상반기에 5%의 생산량을 확보하고 있으며 점차 해외 주문을 받고 있습니다.이 회사는약속국내 이전 주문뿐만 아니라 해외 기반을 통해 글로벌 범위를 확장하며 공급망 구조화 속에서 글로벌 시장 점유율을 지속적으로 늘릴 수 있습니다.3월 2일 초기 거래 기준지난 2월 27일, 일일 거래액은 1억 8천 8백만 주식을 기록하며 거래액은 9억 원에 달했다.853억 위안, 매출률 6.11%로 지속적인 활발한 시장 거래와 긍정적 인 장기 성장 기대를 나타냅니다.

- - - - - - - - -

출처: 오늘의 뉴스 헤드라인

면책: 우리는 독창성과 가치 공유를 존중합니다. 텍스트와 이미지의 저작권은 원래의 저작자에게 있습니다.

더 보기

동박 적층판 산업, 생산 확대 잇따라… 핵심 소재 국산화 가속

2026-01-27

"최근 우리가 이해한 바에 따르면,구리 피복 라미네이트산업은 새로운 번영의 사이클에 진입하고 있습니다. 국내 유명 페놀수지 업체의 한 고위 임원은 1월 25일 증권타임스 기자에게 "중국 설 연휴에도 문을 닫지 않는 기업도 있다"며 "국내 CCL 산업이 부흥하는 과정에서 핵심소재 국산화가 가속화될 것으로 예상된다"고 말했다.

기업들, 고성능 CCL 생산 확대CCL(Copper-Clad Laminate)은 페놀수지의 주요 응용 분야입니다. 앞서 언급한 페놀수지 회사의 다운스트림 CCL 고객으로는 Taiwan Union Technology Corporation, ITEQ, Shengyi Technology(600183), Huazheng New Material(603186), Jin'an Guojie(002636), Nan Ya New Material(688519) 등이 있습니다.

이어 "AI 서버, 자동차 전장(885545), 광통신 등 수요가 급증하면서 CCL 업체들이 회복세를 보이고 있다. 최근 한 CCL 업체를 방문하고 돌아왔는데 이들은 2026년 전망에 대해 상당히 낙관적이다. 긴급한 고객 주문으로 인해 춘절에도 문을 닫을 계획은 없다"고 덧붙였다.

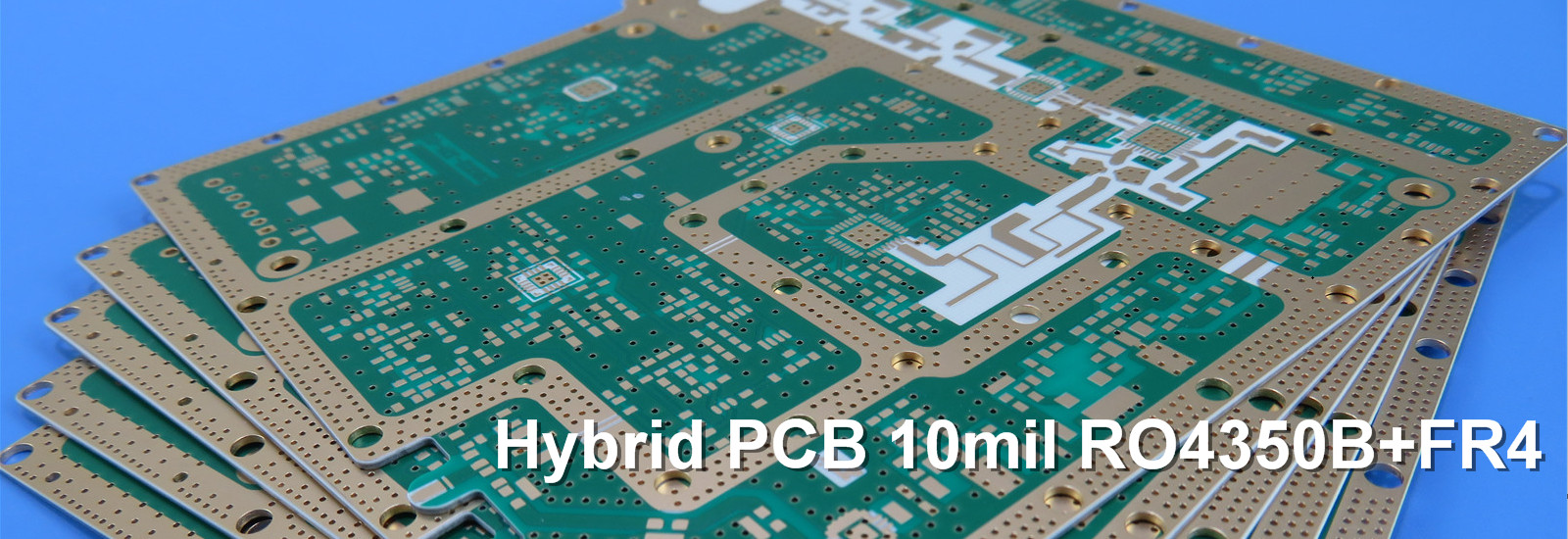

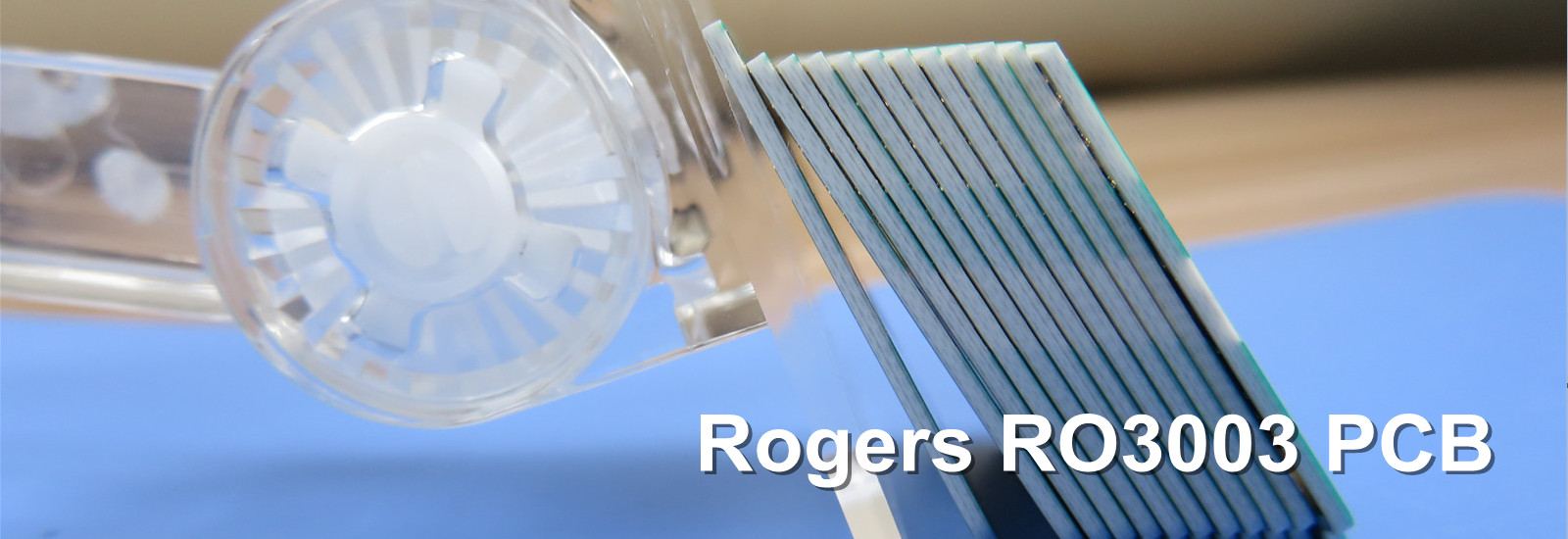

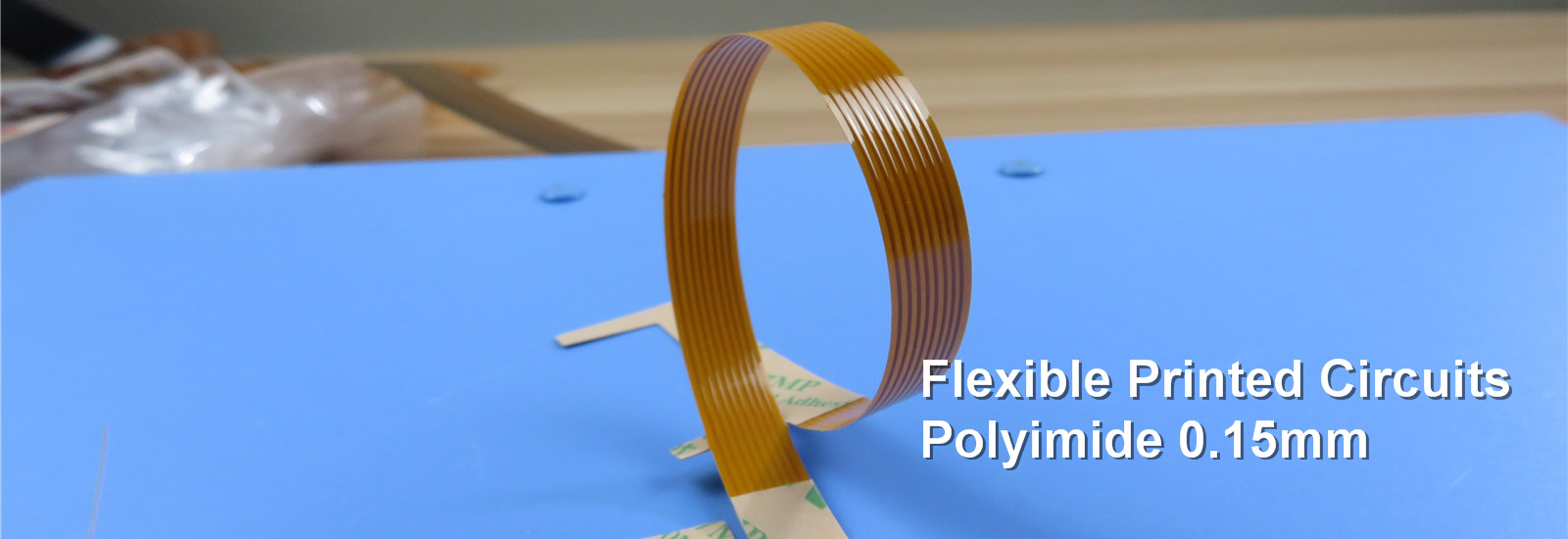

CCL은 통신 장비(881129), 자동차 전자 장치(885545), 가전 제품(881124), 반도체(881121) 등을 포함한 최종 응용 시나리오를 갖춘 PCB(인쇄 회로 기판(884092)) 제조를 위한 업스트림 재료로 이해됩니다. 향후 3~5년 동안 PCB 산업의 성장은 주로 "AI 컴퓨팅 인프라 + 자동차 전자 장치"라는 이중 엔진에 의해 주도될 것입니다. (885545) 지능." 동시에 첨단 패키징(886009), 엣지 AI 하드웨어, 고주파 통신 등 분야가 구조적 성장 기회를 제공할 것이다. 업계가 고급화, 고부가가치 제품으로 업그레이드되는 추세는 분명합니다.

최근 AI 서버 수요 급증으로 인해 고급 원자재 공급이 부족해지면서 글로벌 리더인 Resonac은 2026년 3월부터 Copper Foil Substrates(CCL)을 포함한 소재에 대해 30% 이상의 포괄적인 가격 인상을 발표했습니다. AI 서버 및 신에너지 차량(850101)의 수요 급증으로 2024년 글로벌 PCB 시장은 880억 달러에 달할 것입니다. 컨설팅업체 Prismark의 예측에 따르면 글로벌 PCB 시장 생산량은 PCB 산업은 2025년에 약 6.8% 성장할 것이며, PCB 산업은 앞으로도 계속 성장하여 2029년까지 약 946억 6100만 달러에 도달하고 연평균 복합 성장률(CAGR)은 약 5.2%에 달할 것입니다.

전세계 생산능력 분포 측면에서 중국은 전세계 PCB 생산능력의 약 50%를 차지하며 절대적인 선두주자가 되었습니다. 주강삼각주(광둥성은 전국 생산량의 40%를 차지), 장강삼각주, 발해림은 3대 핵심 제조 벨트를 형성합니다. 비용 요인으로 인해 동남아시아(513730)는 중저가 PCB 생산능력 일부 이전에 착수했습니다.

물에 가장 가까운 사람이 먼저 온도를 압니다. 기자는 2~3년의 장기 침체 이후 업스트림 CCL 기업들이 강력한 회복을 경험하고 있으며 연간 실적 예측에서 긍정적인 결과를 보고하고 있다고 언급했습니다. 예를 들어 Jin'an Guojie(002636)는 2023년과 2024년에 각각 1억 1천만 위안과 8,236만 위안의 비경상 항목을 공제한 후 순손실을 보고했습니다. 그러나 2025년 하반기에는 회사 실적이 가속화되어 연간 순이익이 655.53%~871.4% 증가할 것으로 예상됩니다. 화정신소재(603186)는 2025년 순이익을 2억6000만~3억1000만 위안으로 전망했다. 전년도 비경상항목 차감 후 순손실 1억1900만 위안에 비해 크게 늘어난 것이다. Nan Ya New Material(688519)은 2025년 1~3분기 순이익 1억 5,800만 위안을 발표해 전년도 연간 이익 5,032만 위안을 초과했다. 업계 리더(883917) Shengyi Technology(600183)는 2025년 첫 3분기 동안 순이익 24억 4300만 위안을 보고했는데, 이는 이미 2024년 전체 순이익 17억 3900만 위안을 넘어섰습니다.

CCL 기업들이 긍정적인 연간 결과를 종합적으로 보고하는 동시에 새로운 생산 확장 라운드를 연속적으로 발표했다는 점은 주목할 만합니다. 1월 4일, Shengyi Technology(600183)는 동관 송산호 첨단산업개발구 관리위원회와 고성능 CCL 프로젝트를 위한 45억 위안 투자 의향 계약을 체결했다고 발표했습니다. 2025년 12월 Nan Ya New Material(688519)은 고급 CCL 생산 확대를 위해 약 9억 위안을 조달하겠다는 사모 계획을 공개했습니다. 2025년 11월 진안궈지에(002636)는 고급 CCL을 포함한 프로젝트에 13억 위안을 조달하겠다는 사모 계획을 공개했다.

국내 대체를 가속화하는 핵심 소재CCL 산업 내 새로운 확장 국면에서 업스트림 핵심소재 공급업체들의 국내 대체가 가속화될 것으로 예상된다. 앞서 언급한 수지회사 관계자는 “최근에는 국내 다수의 고급수지와 핵심소재가 제품 성능향상에 있어 괄목할 만한 진전을 이루었고 이제는 외국산 수지를 대등하게 대체할 수 있게 됐다”고 말했다. "국내 대체의 위기를 감지한 다이하치화학공업(850102)이 최근 인계 난연제 대리점이 되기를 희망하며 우리 회사에 접근했지만 우리는 거절했습니다."

그 임원은 다음과 같은 예를 들었다. "현재 우리는 수지를 생산하는 동시에 Wansheng Co., Ltd.(603010)의 두 가지 특수 인계 난연제 에이전트이기도 합니다. 우리 회사의 기존 채널 장점과 Wansheng 자체 제품의 비용 효율성을 활용하여 여러 CCL 회사에 제품을 소개했습니다. 이전에는 이들 회사의 특수 난연제 사용이 대부분 외국 회사에 의해 독점되었습니다."

이러한 진술과 관련하여 기자는 회사의 공개 정보를 검토한 결과 웨이팡 기지의 고급 PCB 업스트림 재료 분야에서 CCL용 난연제와 PCB 포토레지스트용 감광성 수지(885864)라는 두 가지 핵심 제품을 이미 배치했다는 사실을 발견했습니다. Wansheng Co., Ltd.(603010)의 한 대표는 기자에게 회사가 다양한 유형의 난연제 및 CCL용 감광성 수지에 대한 다양한 공급 능력을 형성하여 지속적으로 경쟁 우위를 확고히 하고 있다고 말했습니다.

다운스트림 인쇄회로기판(PCB) 제조 산업의 지속적인 확장과 전자 제품의 화재 성능에 대한 요구 사항 증가로 인해 에폭시 CCL에 사용되는 난연제에 대한 글로벌 시장 수요는 빠른 성장 추세를 보일 것으로 예상됩니다. 할로겐 연소로 인해 발생하는 유해가스와 안티몬계 난연제의 잠재적인 발암 위험성을 방지하고, 우수한 열 안정성과 난연 효율을 지닌 할로겐프리 인계 난연제는 고급형 CCL에서 적용 비율이 크게 증가하고 있습니다.

관련된 수지 유형에는 전자 등급 에폭시 수지, 전자 등급 페놀 수지 등이 포함되는 것으로 이해됩니다. 그중 전자 등급 수지는 CCL의 "특성 조정자" 역할을 합니다. 서로 다른 수지는 CCL의 다양한 특성을 향상시킬 수 있으며, 결과적으로 CCL 특성의 업그레이드는 PCB 성능을 향상시킵니다. 예를 들어, 수지의 극성 그룹 구조와 경화 방법은 CCL의 동박 박리 강도와 층간 결합력에 영향을 미쳐 PCB 가공의 신뢰성을 높여줍니다. 수지에 브롬계 또는 인계 난연 성분이 많을수록 CCL의 난연 등급이 높아집니다. 특수 구조는 또한 저유전 특성과 고유 난연성을 달성할 수 있어 차세대 서버, 자동차 전자 장치(885545), 통신 네트워크 및 기타 분야에서 널리 사용되는 고주파 신호 전송 및 고속 정보 처리에 대한 요구를 충족합니다.

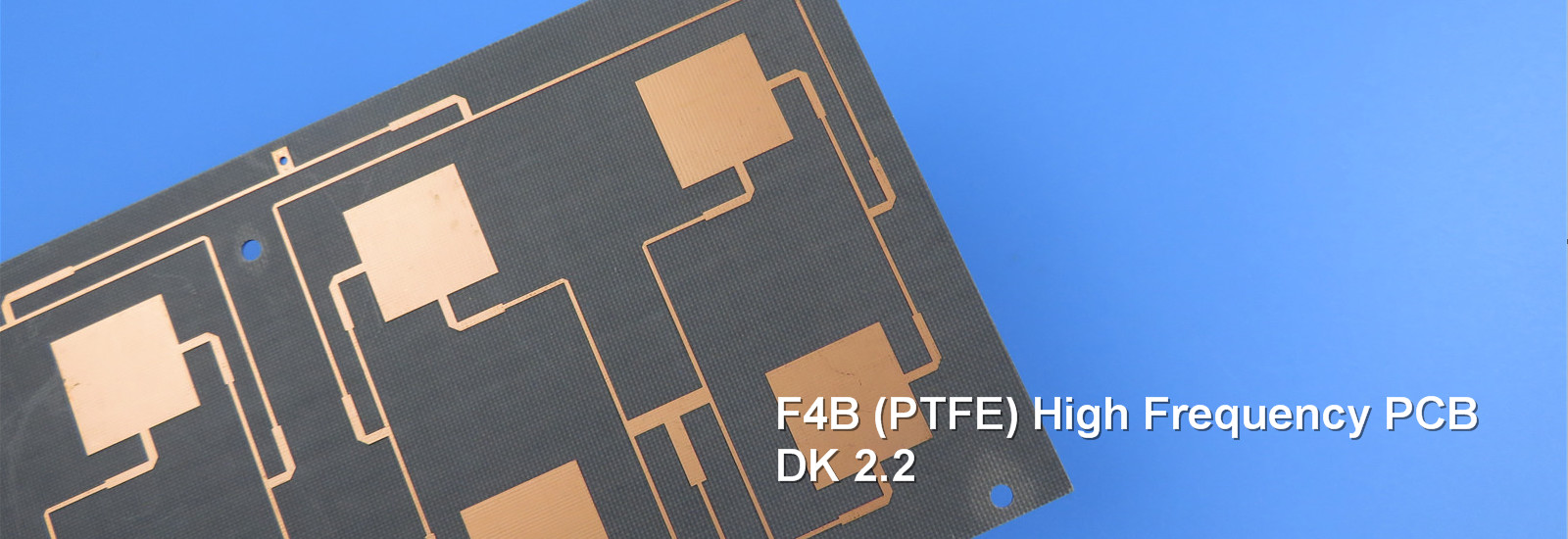

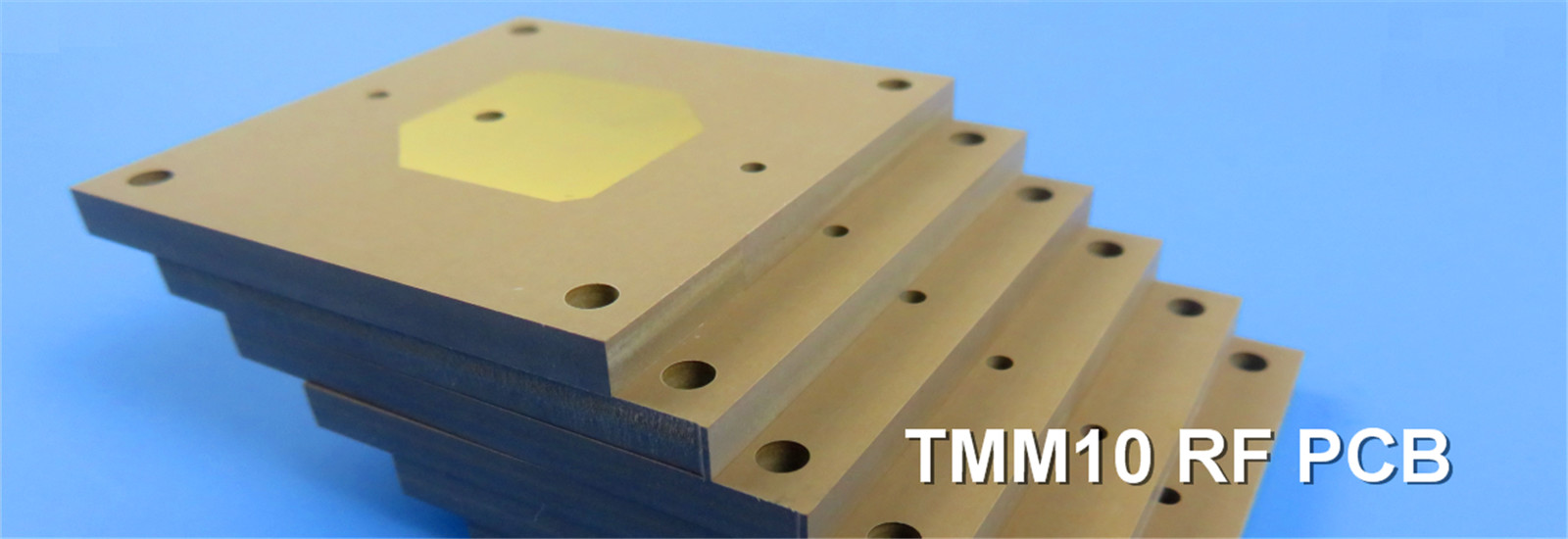

고주파 CCL을 예로 들면, 이러한 제품은 초고주파 시나리오에 적합한 5GHz 이상의 주파수에서 작동하는 초고주파 신호용 "특수 수신기"입니다. 이는 초저 유전 상수(Dk)와 가능한 한 낮은 유전 손실(Df)을 요구합니다. 5G 기지국과 자율주행(885736), 밀리미터파 레이더(886035), 고정밀 위성항법(885574) 등의 핵심소재다. Dk를 낮추려면 주로 절연 수지, 유리 섬유 및 전체 구조를 수정하는 데 의존합니다.

업계 관계자들은 전 세계 전자 산업이 "무할로겐, 고성능, 고신뢰성"으로 업그레이드됨에 따라 PCB 업스트림 재료(특히 난연제 및 CCL)에 대한 성능 요구 사항이 계속 증가하여 기술 우위를 갖춘 재료 회사에 새로운 시장 기회를 제공한다고 믿습니다. 이들 기업은 중저가 시장 내 국내 대체 시장에서 선점자 우위를 확보하게 될 것입니다. 특히 Wansheng Co., Ltd.(603010)는 CCL용 난연제와 PCB 포토레지스트용 감광성 수지라는 두 가지 핵심 제품 라인을 미리 마련해 산업 성장과 국내 대체의 이점을 충분히 누릴 것입니다.

----------------------------------

출처 : 증권타임즈e사면책 조항: 우리는 독창성을 존중하고 공유의 가치도 존중합니다. 글과 이미지의 저작권은 원저작자에게 있습니다. 재인쇄의 목적은 더 많은 정보를 공유하기 위한 것이며, 이는 이 계정의 입장을 대변하지 않습니다. 귀하의 권리가 침해된 경우, 즉시 당사에 연락해 주시면 최대한 빨리 해당 콘텐츠를 삭제해 드리겠습니다. 감사합니다.

더 보기

MSL이란 무엇인가요? PCB SMT 작업장에서의 습기 방지 보관 가이드

2026-01-27

SMT (Surface Mount Technology) 생산 과정에서 PCB 및 부품의 습도 민감성 문제는 용접 성과와 제품 신뢰성에 직접 영향을 미칩니다.습도 민감도 수준 (MSL) 은 보호 표준을 정의하는 핵심 지표입니다.. 표준화 된 작업실 저장 조건과 결합하면 수분 흡수로 인한 생산 장애를 효과적으로 예방 할 수 있습니다. PCB는 왜 수분을 두려워합니까? MSL 등급은 무엇입니까?

PCB 기판 (FR-4 등) 은 공기로부터 수분을 쉽게 흡수합니다. SMT 재흐름 용접의 높은 온도 (> 220 °C) 에서 내부 수분이 빠르게 증발하고 팽창합니다.소금 패드에서 보드 탈lamination 또는 마이크로 균열을 초래할 수 있습니다 ("팝콘 효과"로 알려져 있습니다)산업은 습도 민감도 수준 (MSL) 표준을 사용하여 1~6 레벨로 나뉘어 이 위험을 수치화합니다.구성 요소가 더 민감할수록, 그리고 허용되는 작업실 노출 시간이 짧을수록:

MSL 레벨 3: 열기 후 168시간 (7일) 이내에 용접해야 합니다.

MSL 레벨 6: 24시간 이내에 용접해야 하며, 사용 전에 습기를 제거하기 위해 종종 구워야 합니다.

SMT 작업실의 저장 및 관리 사양은 MSL 요구 사항에 기반합니다. 현대 SMT 작업실은 엄격한 습도 민감성 물질 제어 시스템을 구축해야합니다.

들어오는 저장: MSL 수치를 명확하게 표시하고 개별적으로 보관하십시오. 표준 재료는 통제된 환경에서 보관됩니다 (일반적으로 온도

더 보기

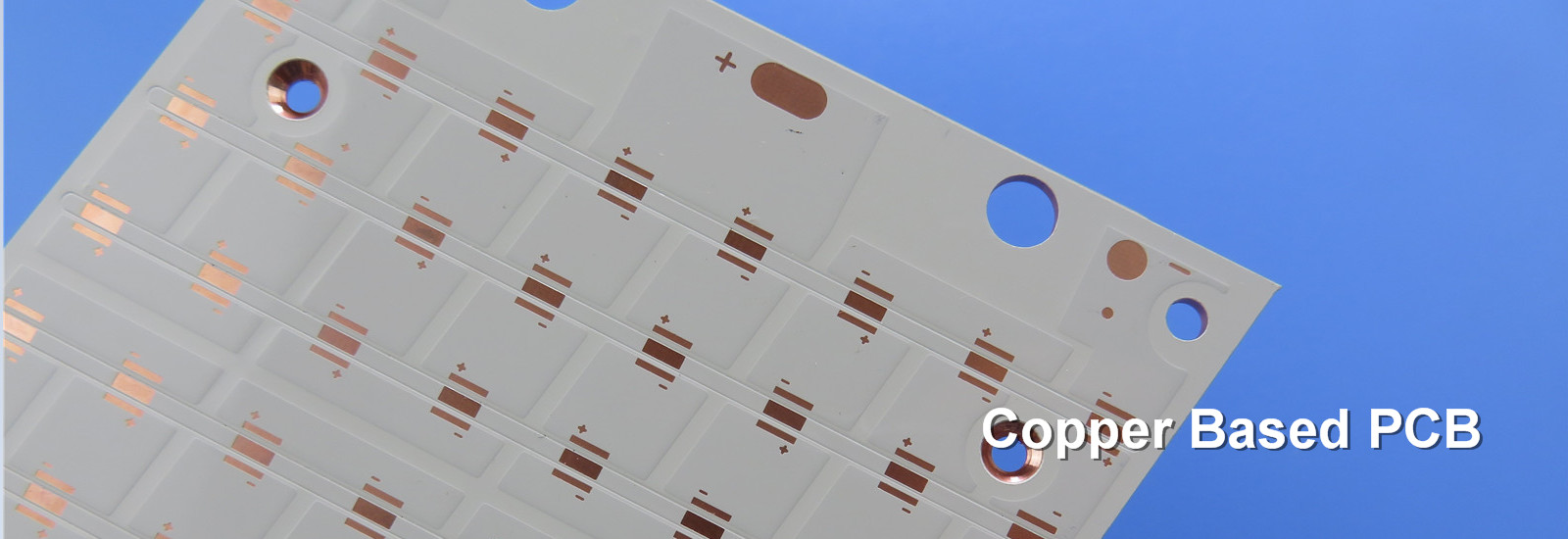

PCB 재료 선택: 금속 클래드 라미네이트 vs. FR-4?

2025-12-18

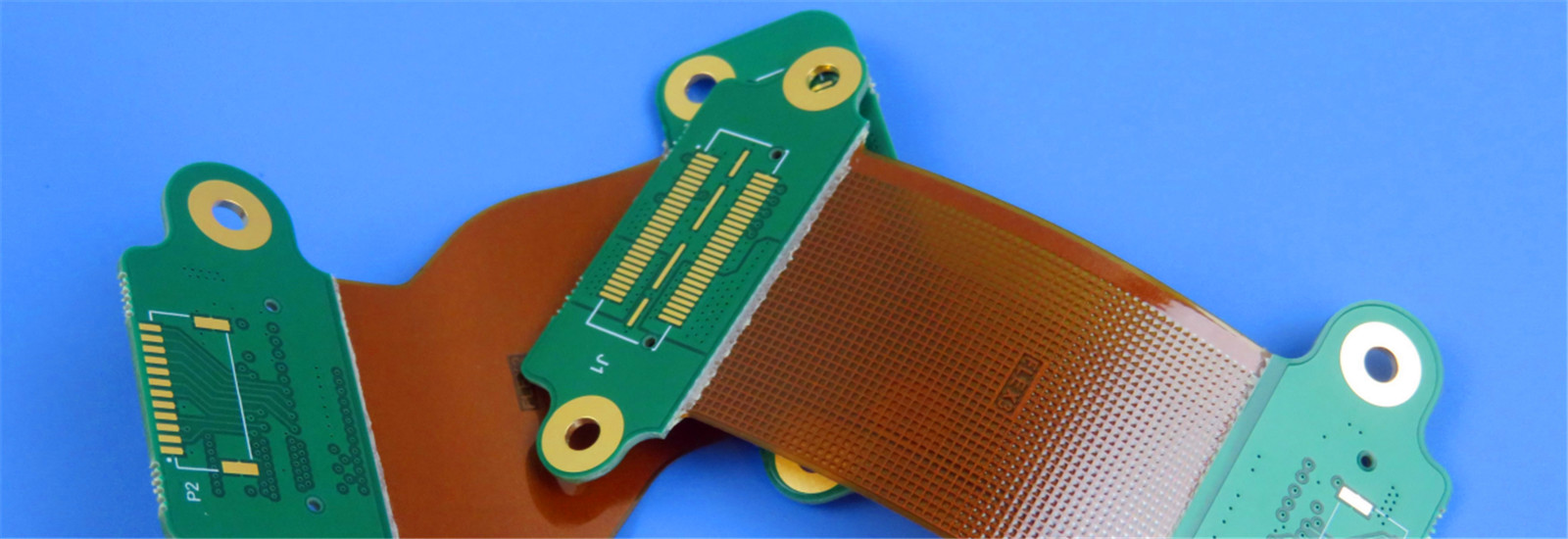

금속 클래드 라미네이트 및 FR-4 는 전자 산업에서 인쇄 회로 기판(PCB)에 일반적으로 사용되는 두 가지 기판 재료입니다. 이들은 재료 구성, 성능 특성 및 적용 분야에서 차이가 있습니다.

금속 클래드 라미네이트 및 FR-4 분석

금속 클래드 라미네이트: 이것은 일반적으로 알루미늄 또는 구리인 금속 베이스를 가진 PCB 재료입니다. 주요 특징은 뛰어난 열 전도율과 방열 능력으로, LED 조명 및 전력 변환기와 같이 높은 열 전도율이 필요한 응용 분야에서 매우 인기가 있습니다. 금속 베이스는 PCB의 핫스팟에서 전체 기판으로 열을 효과적으로 전달하여 열 축적을 줄이고 장치의 전반적인 성능을 향상시킵니다.

FR-4: FR-4는 유리 섬유 천을 보강재로, 에폭시 수지를 바인더로 사용하는 라미네이트 재료입니다. 이는 우수한 기계적 강도, 전기 절연 특성 및 난연 특성으로 인해 선호되어 다양한 전자 제품에 적합한 가장 널리 사용되는 PCB 기판입니다. FR-4는 UL94 V-0의 난연 등급을 가지며, 이는 화염에 노출되었을 때 매우 짧은 시간 동안 연소됨을 의미하여 높은 안전 요구 사항이 있는 전자 장치에 적합합니다.

금속 클래드 라미네이트와 FR-4의 주요 차이점

1. 베이스 재료: 금속 클래드 라미네이트는 금속(알루미늄 또는 구리 등)을 베이스로 사용하는 반면, FR-4는 유리 섬유 천과 에폭시 수지를 사용합니다.

2. 열 전도율: 금속 클래드 라미네이트는 FR-4보다 열 전도율이 훨씬 높아 효과적인 방열이 필요한 응용 분야에 적합합니다.

3. 무게 및 두께: 금속 클래드 라미네이트는 일반적으로 FR-4보다 무겁고 더 얇을 수 있습니다.

4. 가공성: FR-4는 가공이 용이하고 복잡한 다층 PCB 설계에 적합하며, 금속 클래드 라미네이트는 가공이 더 어렵지만 단층 또는 간단한 다층 설계에 이상적입니다.

5. 비용: 금속 클래드 라미네이트는 금속의 높은 비용으로 인해 일반적으로 FR-4보다 비쌉니다.

6. 적용 분야: 금속 클래드 라미네이트는 전력 전자 장치 및 LED 조명과 같이 우수한 방열이 필요한 전자 장치에 주로 사용됩니다. FR-4는 더 다재다능하며 대부분의 표준 전자 장치 및 다층 PCB 설계에 적합합니다.

요약하면, 금속 클래드 라미네이트와 FR-4 중에서 선택하는 것은 주로 제품의 열 관리 요구 사항, 설계 복잡성, 비용 예산 및 안전 고려 사항에 따라 달라집니다. JDB PCB는 가장 진보된 재료가 반드시 가장 적합한 것은 아니므로 제품의 특정 요구 사항에 따라 재료를 선택할 것을 권장합니다.

------------------------------

저작권 고지: 위의 텍스트 및 이미지에 대한 저작권은 원저작자에게 있습니다. Bicheng 은 이를 재게시합니다. 저작권 관련 문제가 있는 경우 당사에 문의하시면 해당 콘텐츠를 삭제하겠습니다.

더 보기